supply High temperature energy-saving centrifugal pump Noise includes pump noise, motor noise and pipeline noise. There is no staff in the assembled pump room during the normal operation of the pump, so the main purpose is to protect the residents around the pump room from being affected. The pump house is mostly used in the basement of residential buildings, High temperature energy-saving centrifugal pump manufactor During operation, the vibration noise of the pump unit spreads along the floor and wall to the upstairs, resulting in obvious vibration of the wall, floor, ceiling and column head of the owner's room upstairs. The room buzz has a serious impact on the human body. Many cities in the north need heating in winter, so many communities have set up heating pump rooms. Ventilation and heat dissipation are required in the pump room, and sound leakage is serious when the pump is running. There will be a high noise sound pressure level outside the pump room, which will seriously affect the quality of life and sleep of residents in the community.

supply High temperature energy-saving centrifugal pump Application in water supply and drainage engineering, High temperature energy-saving centrifugal pump manufactor Introduction! In recent years, the speed of economic development in China has risen straightly, and GDP is in a steady growth state, which shows that people's living standards are constantly improving. But for the utilization of water resources, people generally have the deep-rooted idea of inexhaustible, which leads to the increasing waste and pollution of water resources. However, at present, the development of urban industrial production has increased the utilization of water resources, so the supply of fresh water resources has presented a shortage problem. In addition, the urban industrial development has aggravated the sewage problem, and the urban sewage problem has gradually become the primary factor threatening the normal development of the city and affecting the urban ecology. Compared with the western developed countries, China's water pollution treatment technology is relatively backward. We must learn from the advanced means and technologies of water pollution treatment in western developed countries, and explore a water pollution treatment road with Chinese characteristics in combination with China's own water pollution treatment status. There may be many problems in the process of exploration, but we must continue to improve and gradually improve the efficiency of water pollution treatment. In many cases, the speed of sewage treatment in China lags far behind the speed of water pollution, while high energy consumption increases the economic load, coupled with the low degree of automation of water pollution equipment, resulting in excessive labor consumption, which will cause difficulties in water pollution treatment in China.

Compared with traditional pump stations, High temperature energy-saving centrifugal pump manufactor The required installation and commissioning time is greatly reduced. supply High temperature energy-saving centrifugal pump The existing integrated sewage pump station is technically improved, and private customization is provided. In addition, why is the price of qualified fire pump not expensive? The correct fire pump manufacturers, especially those with full qualifications and years of experience, are first of all professional enough in production technology. The working procedures of the system machine, submersible sewage pump and other main control equipment are fed into the PLC machine to achieve automatic operation, so as to reduce the operating workload and reduce unnecessary human damage. The ground occupies only a few square meters, so space is saved. Precautions when selecting comprehensive sewage pump station, remember! The sewage comprehensive pump station has a great impact on sewage treatment, and is a favorite sewage treatment product of many units and enterprises.

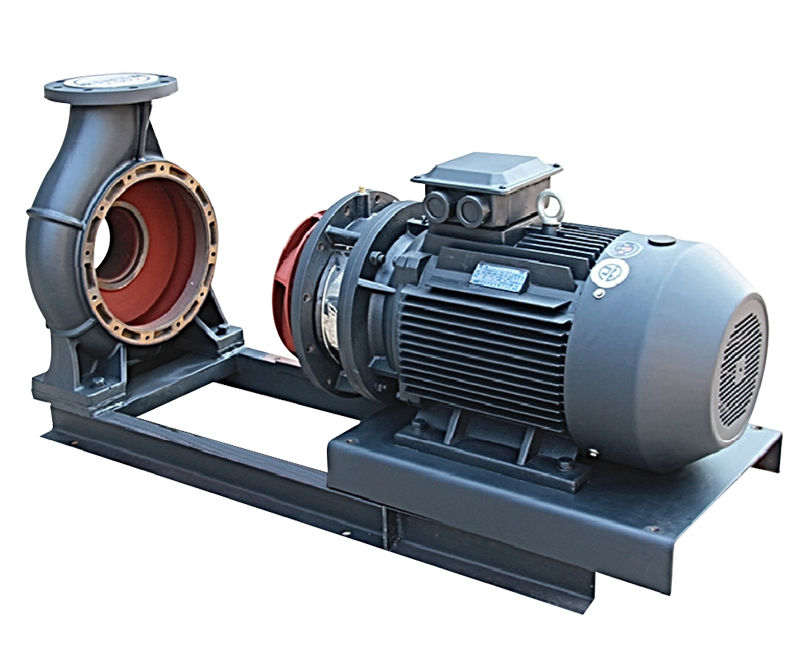

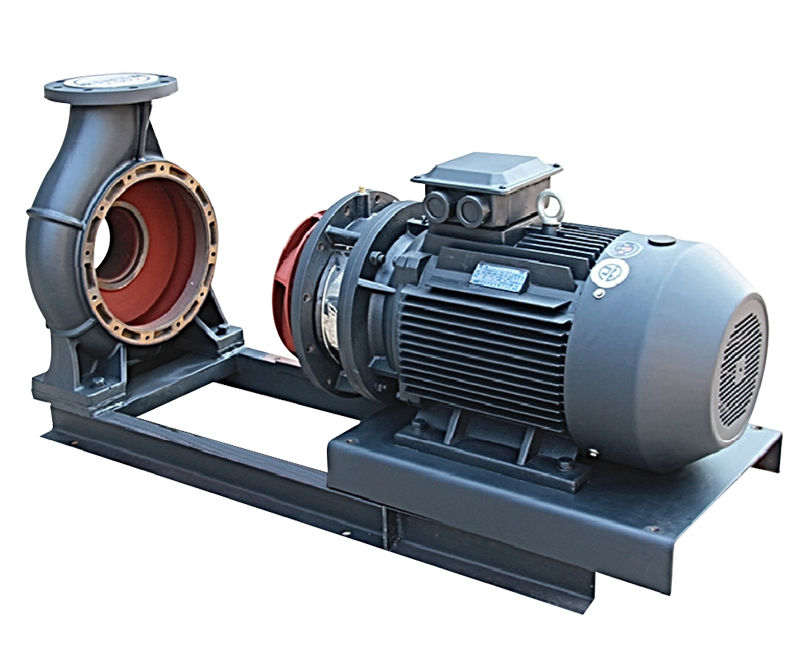

High temperature energy-saving centrifugal pump manufactor The integrated prefabricated pump station is a comprehensive urban drainage and water supply device that provides potential energy and pressure energy for water. It is composed of cylinders, pipelines, electromechanical equipment, electrical control and other ancillary facilities, and is scientifically matched, reasonably designed and assembled. Its drainage performance, safety performance and operation reliability directly determine the safety of urban drainage and water supply. supply High temperature energy-saving centrifugal pump The demander's requirements for its performance are also getting higher and higher, so detection is the way to obtain the demander's approval.

supply High temperature energy-saving centrifugal pump "Good, fast and economical" Talking about the advantages of prefabricated pump house, High temperature energy-saving centrifugal pump manufactor He said, "First of all, the quality of prefabricated concrete components is controllable, the deviation of appearance surface flatness is small, and the concrete strength of prefabricated products can reach C40, which is conducive to improving the instability of concrete quality of traditional cast-in-place structures; Secondly, the construction period is controllable. Prefabricated components are produced in factories, and on-site installation is mechanically hoisted, which is safe and convenient, and can also significantly reduce the use of labor. The project duration can be free from the impact of natural weather and other factors; The third is energy conservation and environmental protection. The main body of the project is mostly prefabricated, and a large number of cement, sand and stone and other dust building materials do not need to enter the site. The construction has little impact on the surrounding urban environment. " The prefabricated steel structure building is a form of prefabricated building with high assembly rate, which covers the components of the system such as structure, enclosure, interior decoration and equipment pipeline. It is prefabricated in the factory, and the integrated module is transported to the construction site for assembly and connection to form a complete building. Fabricated steel structure buildings have the advantages of high standardization and high integration, which can greatly reduce the entire construction cycle.