recommend Vertical centrifugal pump Application in water supply and drainage engineering, Vertical centrifugal pump Manufacturer Introduction! In recent years, the speed of economic development in China has risen straightly, and GDP is in a steady growth state, which shows that people's living standards are constantly improving. But for the utilization of water resources, people generally have the deep-rooted idea of inexhaustible, which leads to the increasing waste and pollution of water resources. However, at present, the development of urban industrial production has increased the utilization of water resources, so the supply of fresh water resources has presented a shortage problem. In addition, the urban industrial development has aggravated the sewage problem, and the urban sewage problem has gradually become the primary factor threatening the normal development of the city and affecting the urban ecology. Compared with western developed countries, China's water pollution treatment technology is relatively backward. We must learn from the advanced means and technologies of water pollution treatment in western developed countries, and explore a water pollution treatment road with Chinese characteristics in combination with China's own water pollution treatment status. There may be many problems in the process of exploration, but we must continue to improve and gradually improve the efficiency of water pollution treatment. In many cases, the speed of sewage treatment in China lags far behind the speed of water pollution, while high energy consumption increases the economic load, coupled with the low degree of automation of water pollution equipment, resulting in excessive labor consumption, which will cause difficulties in water pollution treatment in China.

recommend Vertical centrifugal pump There were few original cast-in-place operations on the site, and the health did not disturb the residents. From then on, we bid farewell to the "gray and hazy" construction site. In addition, the reuse rate of steel formwork and other materials has been improved, and the waste, loss and energy saving can be reduced by more than half. It can be seen that, Vertical centrifugal pump Manufacturer It makes up for the shortcomings of the existing reinforced concrete operations, and the quality of the houses is also very good, which is acceptable to the public. Think about the future when prefabricated housing becomes the main construction industry in China, there will be no more dust flying around the construction site and no more construction waste everywhere. At present, the environment in our country is getting worse and worse. It can be seen that the energy-saving pump room is not only good, but also very promising.

Vertical centrifugal pump Manufacturer This paper introduces the advantages of the assembled steel structure building: 1. Standardization: standardization is the basis of modular construction. The standardization of module geometric size, connection mode, module combination form, internal parts, equipment and facilities is the basic guarantee to realize rapid and high-quality construction. 2. Modularization: all functional spaces are composed of modules with a high degree of standardization, which fully reflects the speed advantages brought by standardization and integration and meets the needs of emergency medical facilities construction. 3. Industrialization: the construction will be completed in a short time, and the designer will make full use of the existing module product size. While processing the floor on site, modules are produced synchronously in the factory. The factory environment and indoor construction conditions will ensure that its quality is easier to control and improve, defects are reduced, product reliability is improved, and production efficiency is high. 4. Assembling: the construction period on site is very short. In addition to wet operations such as floor leveling and foundation treatment, other parts of the site, such as equipment pipeline installation, door and window installation, indoor facilities installation, etc., are completely dry construction. Different types of work cross each other. Compared with traditional construction methods, it saves time, recommend Vertical centrifugal pump Construction and decoration waste will also be reduced by about 70%.

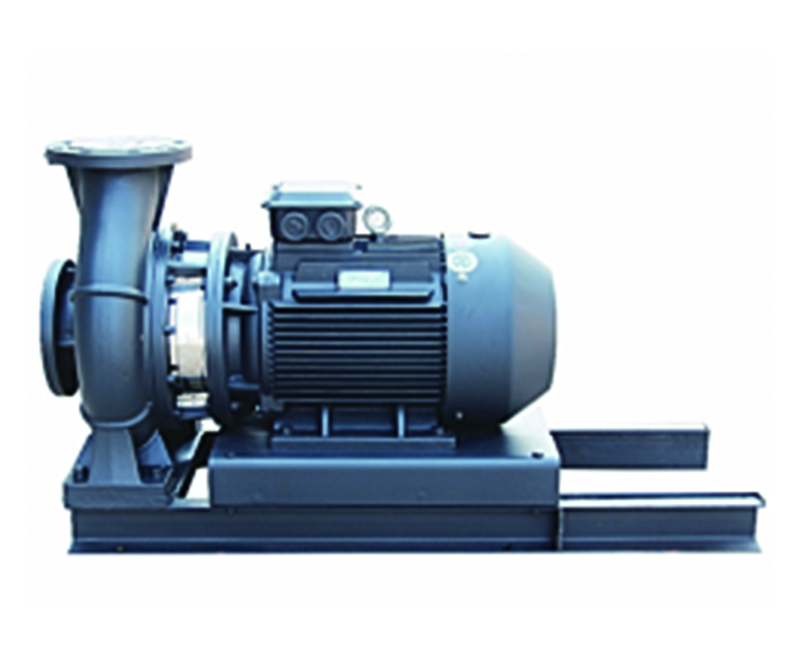

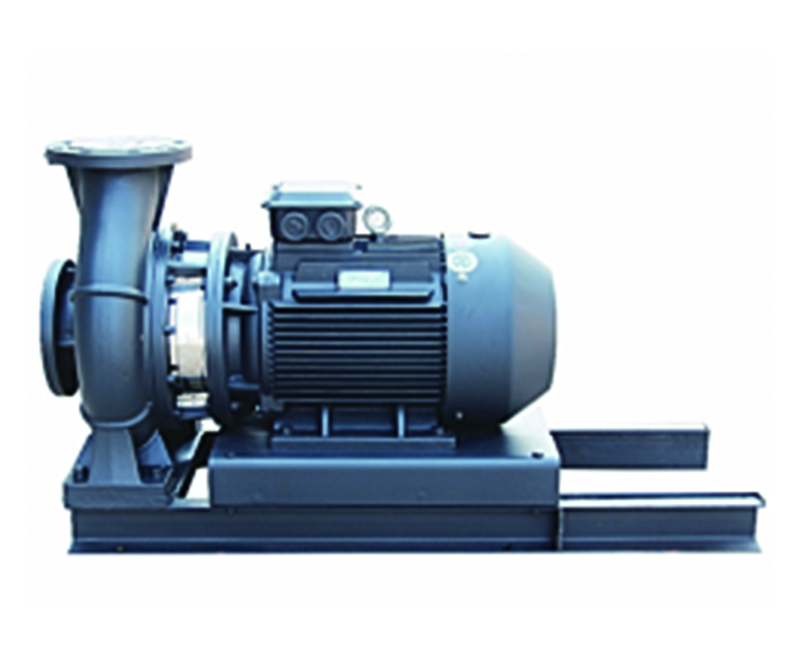

recommend Vertical centrifugal pump What is it? Vertical centrifugal pump Manufacturer What can I do? We often hear that pump stations have many uses, and are dazzled by various articles. It seems that the more we understand them, the more difficult it is to understand them. Then we will talk about some introductions of pump stations and what they can do. First of all, the pump station looks ordinary to us. Its exterior is dark green glass fiber reinforced plastic cylinder, which seems very simple, but it is not. In fact, the internal structure of the pump station can be very complex and diverse. In the dark green shell of the integrated pump station, there are many parts and components. The core of the pump station we are talking about is the water pump. For pump stations of some sizes, there is not only one water pump, but basically all of them are from the water pump unit. As for the model selection of the pump, the previous articles have also talked about it, so I will not say much here.

In recent years, with the construction of more and more pump houses around the country, problems related to them have become increasingly apparent, Vertical centrifugal pump Manufacturer Management and maintenance, water pollution, safety management and other issues are gradually exposed. How to further strengthen the management level of the above pump room facilities and equipment, further improve and ensure the safe water supply capacity, and manage and maintain all kinds of facilities and equipment in the pump room has become the common concern and work direction of all major water supply management enterprises and water supply equipment manufacturers. Standardized standard pump room construction and management introduced, recommend Vertical centrifugal pump Mainly based on the optimized configuration and construction of various facilities and equipment in the pump room, the computer network information technology is used to organically integrate various nodes in the pump room. At the same time, in combination with the local economic construction level, according to the actual situation and budget needs of the project, a reasonable standardized construction, management and maintenance scheme is provided and implemented for various pump rooms. Its core is the safe full frequency conversion control pressurization equipment, followed by the integration of computer network information system, and the safety management and maintenance of the whole life cycle.

Vertical centrifugal pump Manufacturer Introduce the basic structure of the integrated pump station: 1 recommend Vertical centrifugal pump The GRP glass fiber reinforced plastic cylinder is made of GRP glass fiber reinforced plastic, and the process is continuous mechanical winding. It is characterized by firmness, durability, non leakage, corrosion resistance, and a service life of 50 years. 2. The base is made of GRP glass fiber reinforced plastic, and the process is molding. It is characterized by anti clogging, anti floating and anti sinking, and its service life can also reach 50 years. 3. The top cover is generally made of embossed aluminum plate, or stainless steel, glass fiber reinforced plastic and other materials, which is used for personnel access. 4. Handrails are made of 304 stainless steel or 316 stainless steel. 5. The control cabinet can be made of 304 stainless steel or 316 stainless steel, which is the core of intelligent control. 6. The flange is made of 304 stainless steel. 7. Check valve, with various stainless steel materials, such as 304, 201, 316, etc. 8. Gate valve is made of 304 stainless steel, or 201, 316, etc. 9. The grating support is made of 304 stainless steel. Similarly, 316 stainless steel can also be selected.