Compared with traditional pump stations, Horizontal end suction pump manufactor The required installation and commissioning time is greatly reduced. supply Horizontal end suction pump The existing integrated sewage pump station is technically improved, and private customization is provided. In addition, why is the price of qualified fire pump not expensive? The correct fire pump manufacturers, especially those with full qualifications and years of experience, are first of all professional enough in production technology. The working procedures of the system machine, submersible sewage pump and other main control equipment are fed into the PLC machine to achieve automatic operation, so as to reduce the operating workload and reduce unnecessary human damage. The ground occupies only a few square meters, so space is saved. Precautions when selecting comprehensive sewage pump station, remember! The sewage comprehensive pump station has a great impact on sewage treatment, and is a favorite sewage treatment product of many units and enterprises.

1. To ensure the safety of the pump room, the pump room must be locked. 2、 Horizontal end suction pump manufactor Safety Operation Regulations, Hygiene and Safety Management System for Secondary Water Supply, Patrol Inspection Specifications, Water Quality Inspection Record System must be posted inside. 3 supply Horizontal end suction pump There must be the following record documents inside: Patrol Inspection Record, Water Tank Blowdown Record, Disinfection Record, Water Quality Inspection Record. 4. The pump room must be marked with the pressurized area, and the corresponding control system should also be marked with the pressurized area: low area, middle area, high area, etc, Mark the product model, qualified number, ex factory date, etc. 6. Water pump identification: the number of pumps must be painted on each pump; For example: 1 # pump, 2 # pump, 3 # pump, 4 # pump, 5 # pump, words. 7. "Normally open" signboard of inlet and outlet valves; 8. The pipe shall be marked with water flow direction arrow; 9. The prefabricated energy-saving pump room needs a drainage system 10. The energy-saving pump room can realize on-site control and remote monitoring;

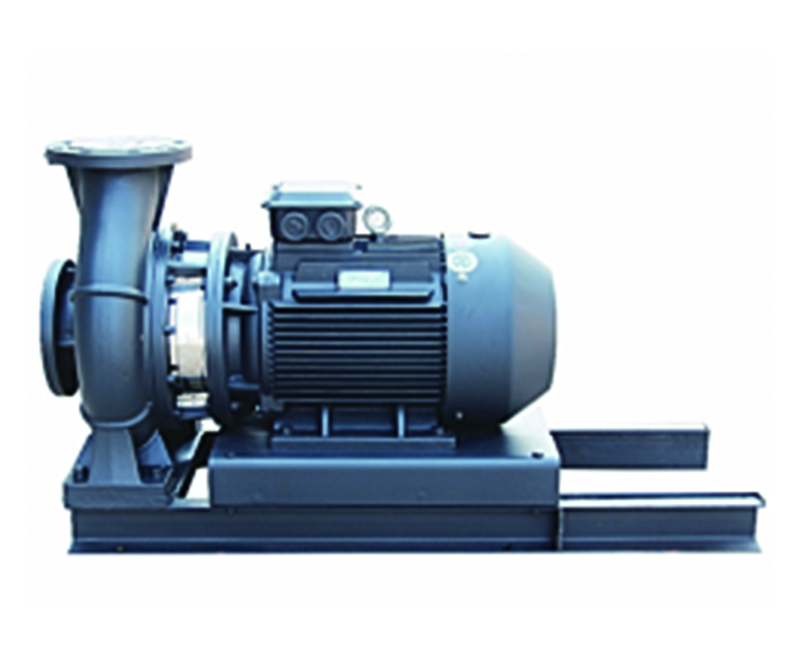

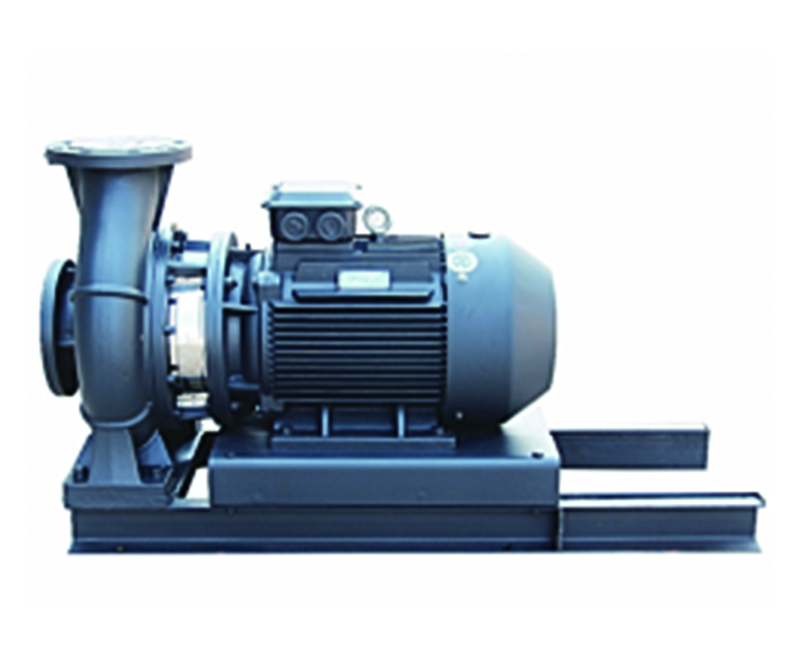

Horizontal end suction pump manufactor The integrated prefabricated pump station is a comprehensive urban drainage and water supply device that provides potential energy and pressure energy for water. It is composed of cylinders, pipelines, electromechanical equipment, electrical control and other ancillary facilities, and is scientifically matched, reasonably designed and assembled. Its drainage performance, safety performance and operation reliability directly determine the safety of urban drainage and water supply. supply Horizontal end suction pump The demander's requirements for its performance are also getting higher and higher, so detection is the way to obtain the demander's approval.

In recent years, with the construction of more and more pump houses around the country, problems related to them have become increasingly apparent, Horizontal end suction pump manufactor Management and maintenance, water pollution, safety management and other issues are gradually exposed. How to further strengthen the management level of the above pump room facilities and equipment, further improve and ensure the safe water supply capacity, and manage and maintain all kinds of facilities and equipment in the pump room has become the common concern and work direction of all major water supply management enterprises and water supply equipment manufacturers. Standardized standard pump room construction and management introduced, supply Horizontal end suction pump Mainly based on the optimized configuration and construction of various facilities and equipment in the pump room, the computer network information technology is used to organically integrate various nodes in the pump room. At the same time, in combination with the local economic construction level, according to the actual situation and budget needs of the project, a reasonable standardized construction, management and maintenance scheme is provided and implemented for various pump rooms. Its core is the safe full frequency conversion control pressurization equipment, followed by the integration of computer network information system, and the safety management and maintenance of the whole life cycle.

Horizontal end suction pump manufactor It is of great significance to use light weight and small volume FRP materials, adopt integrated structural design, and occupy a small area, effectively relieving the current situation of land resource tension. During the design and development of the pump station, advanced innovative ideas were introduced to provide people with high-quality life services. supply Horizontal end suction pump On the premise of liberating human resources, it has realized the treatment of domestic sewage and rainwater, and the sewage treatment effect is also very good. On the premise of ensuring the functional requirements of the pump station, the impact of the construction and use of the pump station on the surrounding environment is minimized, which effectively promotes the promotion and application of the pump station.