recommend Horizontal end suction pump Look at the trend of future architectural situation? Horizontal end suction pump manufactor Let's talk about it: the house is a place for people to shelter from wind and rain at the beginning, but with the development of society and the improvement of living standards, people continue to pursue a comfortable living environment. While improving the construction level, they install various heating and cooling equipment to solve the problem of heating and cooling, and install fresh air and humidity control equipment to solve the problem of indoor ventilation and humidity. At present, the comfort of the house has reached the standard of constant temperature, humidity, oxygen and cleanliness. However, the energy consumption of buildings has been increasing, accounting for 30-40% of the total energy consumption of the society, resulting in an energy crisis, and the environment is getting worse and worse, which seriously affects the sustainable development of society. How can we not only meet the requirements of living comfort today, but also fundamentally reduce energy consumption? This is a subject that has been studied all over the world.

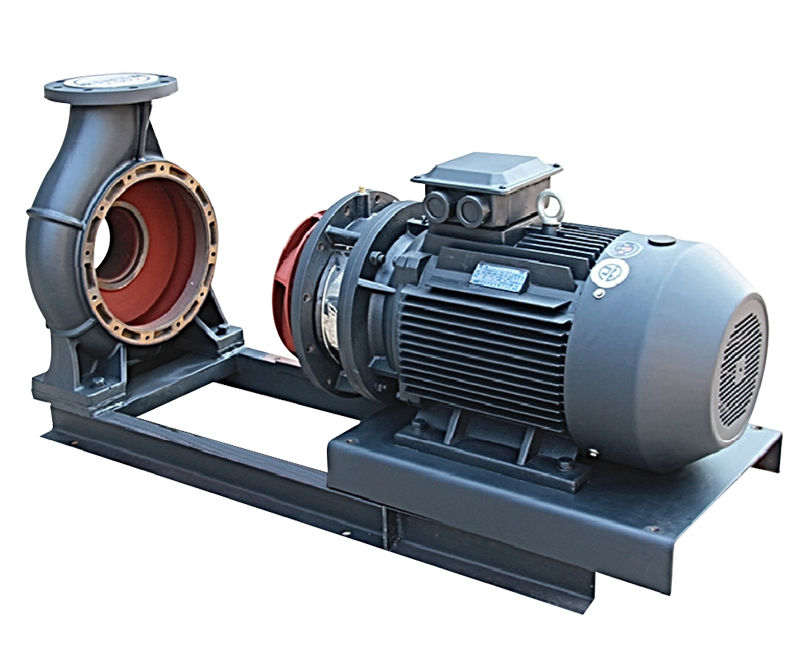

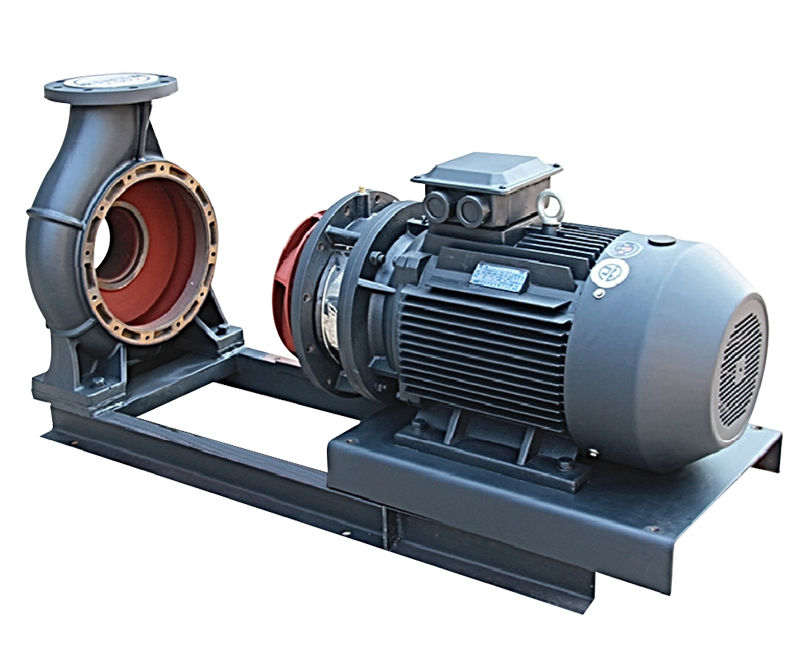

In recent years, with the construction of more and more pump houses around the country, problems related to them have become increasingly apparent, Horizontal end suction pump manufactor Management and maintenance, water pollution, safety management and other issues are gradually exposed. How to further strengthen the management level of the above pump room facilities and equipment, further improve and ensure the safe water supply capacity, and manage and maintain all kinds of facilities and equipment in the pump room has become the common concern and work direction of all major water supply management enterprises and water supply equipment manufacturers. Standardized standard pump room construction and management introduced, recommend Horizontal end suction pump Mainly based on the optimized configuration and construction of various facilities and equipment in the pump room, the computer network information technology is used to organically integrate various nodes in the pump room. At the same time, in combination with the local economic construction level, according to the actual situation and budget needs of the project, a reasonable standardized construction, management and maintenance scheme is provided and implemented for various pump rooms. Its core is the safe full frequency conversion control pressurization equipment, followed by the integration of computer network information system, and the safety management and maintenance of the whole life cycle.

recommend Horizontal end suction pump As the underground installation is adopted, it can be directly installed around the residential area, and because of its small floor area, the characteristics of the whole underground installation will not affect the lives of residents. The harmony and unity with the surrounding environment can be achieved through the landscape control room above the ground. Horizontal end suction pump manufactor It is used in places that cannot rely on gravity to discharge sewage by itself. Waste water below the water level of the waterway is collected through the sewage tank, as well as waste water discharged far away from the municipal sewage pipe network and sanitary facilities, and sewage is transported to the sewage pipe network with the help of the sewage pump.

Horizontal end suction pump manufactor This paper introduces the advantages of the assembled steel structure building: 1. Standardization: standardization is the basis of modular construction. The standardization of module geometric size, connection mode, module combination form, internal parts, equipment and facilities is the basic guarantee to realize rapid and high-quality construction. 2. Modularization: all functional spaces are composed of modules with a high degree of standardization, which fully reflects the speed advantages brought by standardization and integration and meets the needs of emergency medical facilities construction. 3. Industrialization: the construction will be completed in a short time, and the designer will make full use of the existing module product size. While processing the floor on site, modules are produced synchronously in the factory. The factory environment and indoor construction conditions will ensure that its quality is easier to control and improve, defects are reduced, product reliability is improved, and production efficiency is high. 4. Assembling: the construction period on site is very short. In addition to wet operations such as floor leveling and foundation treatment, other parts of the site, such as equipment pipeline installation, door and window installation, indoor facilities installation, etc., are completely dry construction. Different types of work cross each other. Compared with traditional construction methods, it saves time, recommend Horizontal end suction pump Construction and decoration waste will also be reduced by about 70%.