Compared with traditional pump stations, Horizontal end suction pump Price The required installation and commissioning time is greatly reduced. recommend Horizontal end suction pump The existing integrated sewage pump station is technically improved, and private customization is provided. In addition, why is the price of qualified fire pump not expensive? The correct fire pump manufacturers, especially those with full qualifications and years of experience, are first of all professional enough in production technology. The working procedures of the system machine, submersible sewage pump and other main control equipment are fed into the PLC machine to achieve automatic operation, so as to reduce the operating workload and reduce unnecessary human damage. The ground occupies only a few square meters, so space is saved. Precautions when selecting comprehensive sewage pump station, remember! The sewage comprehensive pump station has a great impact on sewage treatment, and is a favorite sewage treatment product of many units and enterprises.

recommend Horizontal end suction pump "Good, fast and economical" Talking about the advantages of prefabricated pump house, Horizontal end suction pump Price He said, "First of all, the quality of prefabricated concrete components is controllable, the deviation of appearance surface flatness is small, and the concrete strength of prefabricated products can reach C40, which is conducive to improving the instability of concrete quality of traditional cast-in-place structures; Secondly, the construction period is controllable. Prefabricated components are produced in factories, and on-site installation is mechanically hoisted, which is safe and convenient, and can also significantly reduce the use of labor. The project duration can be free from the impact of natural weather and other factors; The third is energy conservation and environmental protection. The main body of the project is mostly prefabricated, and a large number of cement, sand and stone and other dust building materials do not need to enter the site. The construction has little impact on the surrounding urban environment. " The prefabricated steel structure building is a form of prefabricated building with high assembly rate, which covers the components of the system such as structure, enclosure, interior decoration and equipment pipeline. It is prefabricated in the factory, and the integrated module is transported to the construction site for assembly and connection to form a complete building. Fabricated steel structure buildings have the advantages of high standardization and high integration, which can greatly reduce the entire construction cycle.

recommend Horizontal end suction pump It is not only reflected in its working ability, but also in its excellent manufacturing process and maintenance costs. The integrated prefabricated pump station is highly integrated, so its volume is very small. It is a good choice for sewage treatment equipment for some factories and business districts that do not have a shortage of land. In addition, Horizontal end suction pump Price The degree of intelligence is very high, so its failure rate is very low. Combined with the application of anti blocking technology, the integrated prefabricated pump station becomes very convenient in the later use, which greatly reduces the labor cost and maintenance cost.

Horizontal end suction pump Price This paper introduces the advantages of the assembled steel structure building: 1. Standardization: standardization is the basis of modular construction. The standardization of module geometric size, connection mode, module combination form, internal parts, equipment and facilities is the basic guarantee to realize rapid and high-quality construction. 2. Modularization: all functional spaces are composed of modules with a high degree of standardization, which fully reflects the speed advantages brought by standardization and integration and meets the needs of emergency medical facilities construction. 3. Industrialization: the construction will be completed in a short time, and the designer will make full use of the existing module product size. While processing the floor on site, modules are produced synchronously in the factory. The factory environment and indoor construction conditions will ensure that its quality is easier to control and improve, defects are reduced, product reliability is improved, and production efficiency is high. 4. Assembling: the construction period on site is very short. In addition to wet operations such as floor leveling and foundation treatment, other parts of the site, such as equipment pipeline installation, door and window installation, indoor facilities installation, etc., are completely dry construction. Different types of work cross each other. Compared with traditional construction methods, it saves time, recommend Horizontal end suction pump Construction and decoration waste will also be reduced by about 70%.

recommend Horizontal end suction pump Application in water supply and drainage engineering, Horizontal end suction pump Price Introduction! In recent years, the speed of economic development in China has risen straightly, and GDP is in a steady growth state, which shows that people's living standards are constantly improving. But for the utilization of water resources, people generally have the deep-rooted idea of inexhaustible, which leads to the increasing waste and pollution of water resources. However, at present, the development of urban industrial production has increased the utilization of water resources, so the supply of fresh water resources has presented a shortage problem. In addition, the urban industrial development has aggravated the sewage problem, and the urban sewage problem has gradually become the primary factor threatening the normal development of the city and affecting the urban ecology. Compared with the western developed countries, China's water pollution treatment technology is relatively backward. We must learn from the advanced means and technologies of water pollution treatment in western developed countries, and explore a water pollution treatment road with Chinese characteristics in combination with China's own water pollution treatment status. There may be many problems in the process of exploration, but we must continue to improve and gradually improve the efficiency of water pollution treatment. In many cases, the speed of sewage treatment in China lags far behind the speed of water pollution, while high energy consumption increases the economic load, coupled with the low degree of automation of water pollution equipment, resulting in excessive labor consumption, which will cause difficulties in water pollution treatment in China.

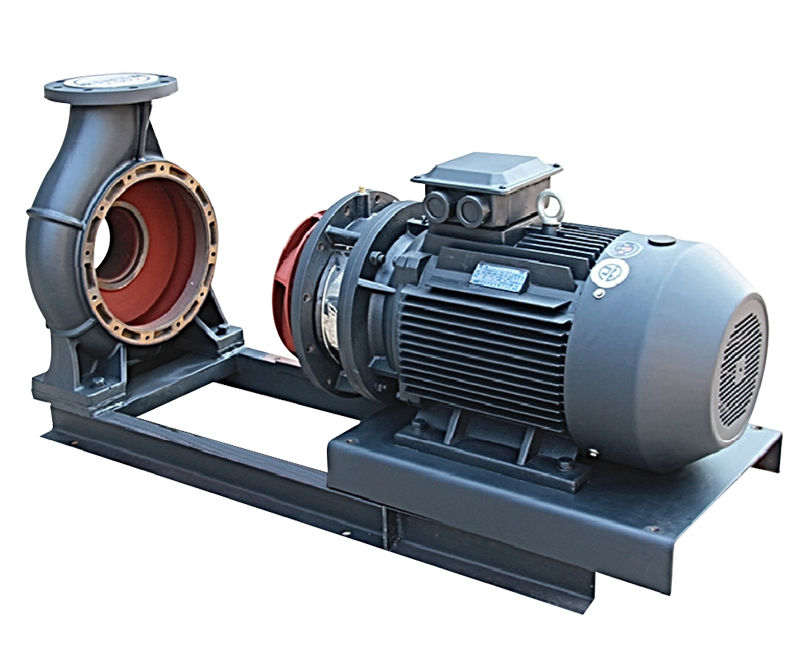

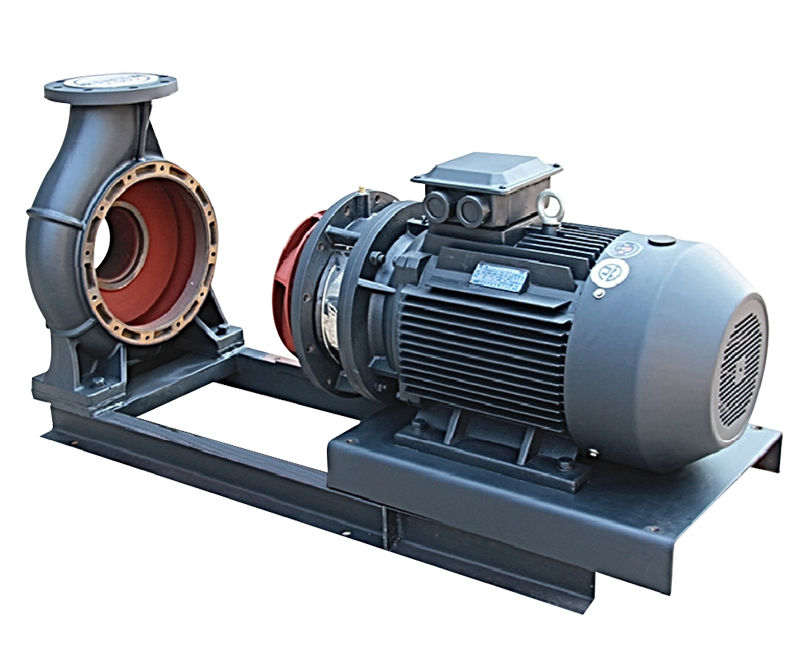

Horizontal end suction pump Price The design principle is: (1) The overall layout should be reasonable, especially for the pump stations that combine irrigation and drainage or self drainage, self diversion and water lifting, as well as the pump stations that combine gates and stations, the layout should be as compact as possible, making full use of buildings for regulation. (2) The selection of pump type shall strive to make the design head of the pump station consistent with the rated head of the pump, and meet the requirements of irrigation and drainage flow. The pump type with advanced technology shall be selected as far as possible to ensure high efficiency of the pump station device and low operation cost. At the same time, the selected pump type should be relatively mature, with certain operation practice, and the test pump type should be avoided as far as possible. (3) The selection of pump type shall fully consider the use and working nature of the integrated pump station. For irrigation and make-up water pump stations with long annual working hours, pumps with wide range, high efficiency and good cavitation performance shall be selected. For those pumping stations focusing on drainage, the pump type with reliable working performance and simple structure shall be selected. (4) The project layout shall adopt positive water inflow as far as possible to ensure that the water inflow condition of each unit is good and the flow pattern is uniform. recommend Horizontal end suction pump When lateral water inflow has to be adopted in the project layout, the distance between the lateral water inlet and the pump shall be extended as far as possible in the design, and certain diversion measures shall be taken. (5) The design of the outlet pool should try to avoid sharp bends that cause water impact and backwater. The pressure water tank shall be designed to avoid the increase of energy loss due to the mutual impact of water flow in each outlet pipe. (6) The construction materials available locally shall be used as far as possible. The design shall ensure simple and convenient construction and less project investment.