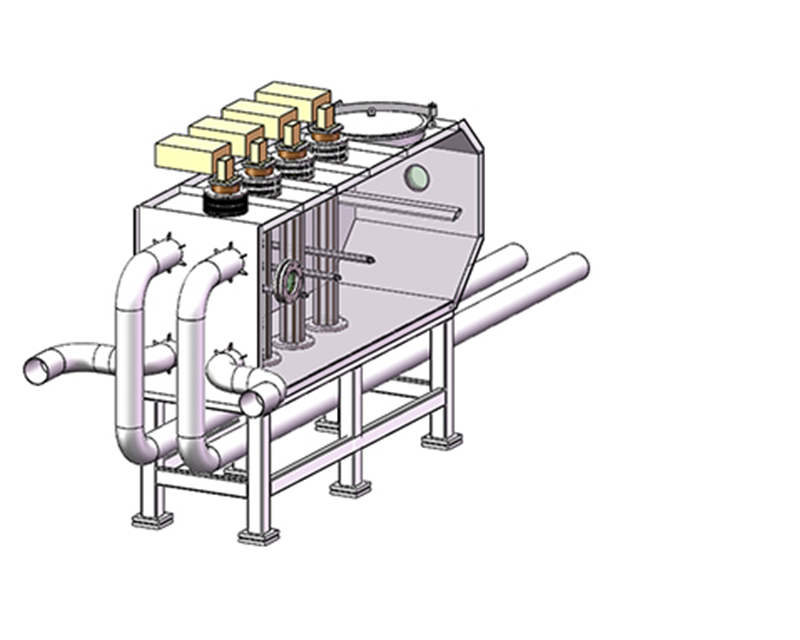

(1) Each UV lamp module assembly includes UV lamp tube, sleeve and module support mechanical automatic cleaning device. The electronic ballast is separately packaged and placed in the ballast cabinet.

(2) Each UV lamp tube is separately placed in a separate quartz sleeve. One end of the sleeve is a closed end, and the other end is sealed by the lamp sealing structure (rubber mechanical sealing structure).

(3) The quartz sleeve is encircled on the frame by the anti ultraviolet material nut and the compression type O-ring, and the rear part is sealed by jacking, so as to avoid any rigid contact between the quartz sleeve and the frame, and prevent the quartz sleeve from being damaged by vibration. The quartz sleeve will not come out during automatic cleaning.

(4) There is no part of the steel structure extending from the frame on both sides of the UV lamp bent at both ends of the quartz sleeve, which can ensure the safety of the quartz sleeve.

(5) The cable connecting the lamp tube shall be terminated in the ballast cabinet above the module, and the protection level shall not be lower than IP65, without water seepage.

(6) The whole module support is made of 304 stainless steel and installed above the sewage in the open channel. The UV lamp module can be conveniently placed on the support without fastening.

(7) The UV lamp rack is designed to facilitate the replacement of lamp tubes and quartz sleeves by the factory operators, and facilitate the operation, installation and maintenance.

(8) The module support is equipped with an ultraviolet reflector to prevent ultraviolet radiation outside the open channel in case of accidents.

(9) Each module is set separately, and it does not need to be fastened to hang above the sewage in the open channel. Therefore, when replacing the lamp tube or quartz sleeve, each module can be lifted separately without affecting other modules.