In recent years, with the construction of more and more pump houses around the country, problems related to them have become increasingly apparent, Pressure vessel manufactor Management and maintenance, water pollution, safety management and other issues are gradually exposed. How to further strengthen the management level of the above pump room facilities and equipment, further improve and ensure the safe water supply capacity, and manage and maintain all kinds of facilities and equipment in the pump room has become the common concern and work direction of all major water supply management enterprises and water supply equipment manufacturers. Standardized standard pump room construction and management introduced, recommend Pressure vessel Mainly based on the optimized configuration and construction of various facilities and equipment in the pump room, the computer network information technology is used to organically integrate various nodes in the pump room. At the same time, in combination with the local economic construction level, according to the actual situation and budget needs of the project, a reasonable standardized construction, management and maintenance scheme is provided and implemented for various pump rooms. Its core is the safe full frequency conversion control pressurization equipment, followed by the integration of computer network information system, and the safety management and maintenance of the whole life cycle.

Pressure vessel manufactor The integrated prefabricated pump station is a comprehensive urban drainage and water supply device that provides potential energy and pressure energy for water. It is composed of cylinders, pipelines, electromechanical equipment, electrical control and other ancillary facilities, and is scientifically matched, reasonably designed and assembled. Its drainage performance, safety performance and operation reliability directly determine the safety of urban drainage and water supply. recommend Pressure vessel The demander's requirements for its performance are also getting higher and higher, so detection is the way to obtain the demander's approval.

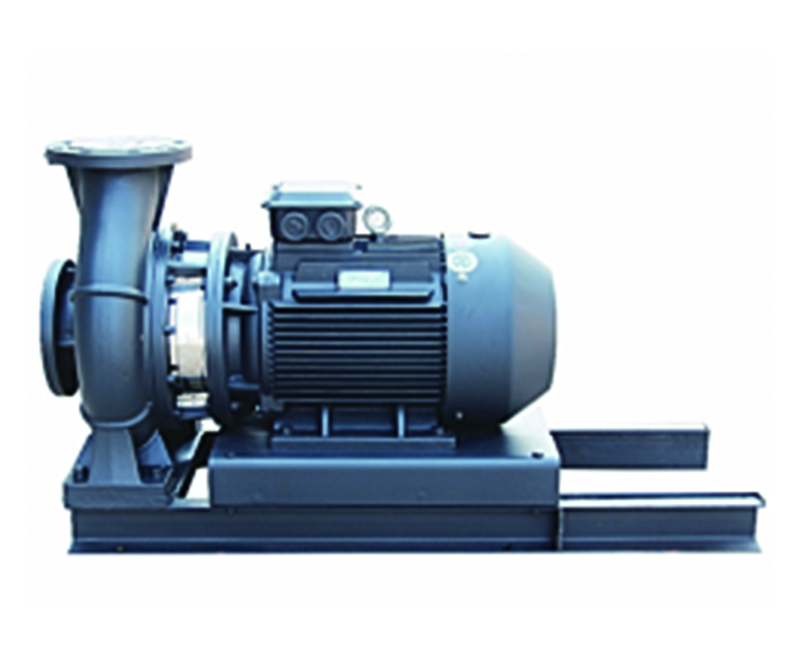

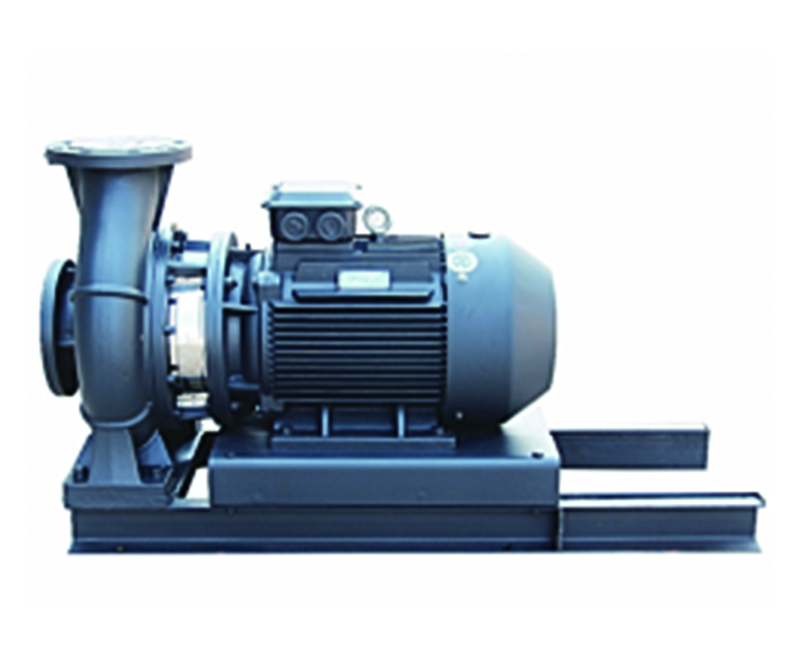

recommend Pressure vessel In the design, there is no such statement as main pump and standby pump. Our statement is that one is in use and one is standby or two is in use and one is standby. They are standby for each other and used in turn. When one is running, the other is the standby pump. Pressure vessel manufactor The first reason for setting a standby pump is to ensure that when the pump is damaged or overhauled, there is still a pump that can work, rather than that we can't use water as long as the pump is broken or regularly overhauled. The second is to let the pump take turns to rest after working for a period of time. To prevent long-term continuous operation from affecting the normal service life of the pump.

recommend Pressure vessel "Good, fast and economical" Talking about the advantages of prefabricated pump house, Pressure vessel manufactor He said, "First of all, the quality of prefabricated concrete components is controllable, the deviation of appearance surface flatness is small, and the concrete strength of prefabricated products can reach C40, which is conducive to improving the instability of concrete quality of traditional cast-in-place structures; Secondly, the construction period is controllable. Prefabricated components are produced in factories, and on-site installation is mechanically hoisted, which is safe and convenient, and can greatly reduce the use of labor. The project duration can be free from the impact of natural weather and other factors; The third is energy conservation and environmental protection. The main body of the project is mostly prefabricated, and a large number of cement, sand and stone and other dust building materials do not need to enter the site. The construction has little impact on the surrounding urban environment. " The prefabricated steel structure building is a form of prefabricated building with high assembly rate, which covers the components of the system such as structure, enclosure, interior decoration and equipment pipeline. It is prefabricated in the factory, and the integrated module is transported to the construction site for assembly and connection to form a complete building. Fabricated steel structure buildings have the advantages of high standardization and high integration, which can greatly reduce the entire construction cycle.

Pressure vessel manufactor It is of great significance to use light weight and small volume FRP materials, adopt integrated structural design, and occupy a small area, effectively relieving the current situation of land resource tension. During the design and development of the pump station, advanced innovative ideas were introduced to provide people with high-quality life services. recommend Pressure vessel On the premise of liberating human resources, it has realized the treatment of domestic sewage and rainwater, and the sewage treatment effect is also very good. On the premise of ensuring the functional requirements of the pump station, the impact of the construction and use of the pump station on the surrounding environment is minimized, which effectively promotes the promotion and application of the pump station.