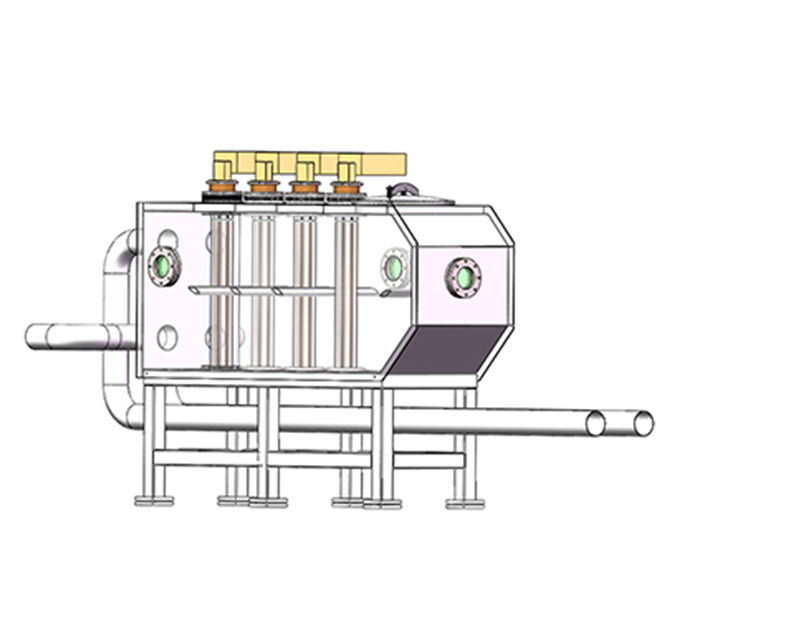

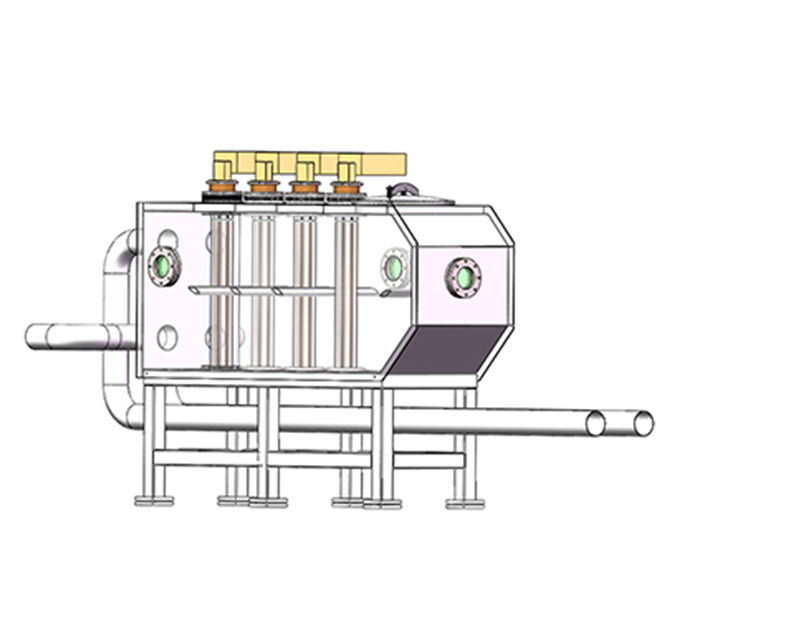

Microwave electrodeless ultraviolet sterilization equipment Beautiful appearance, compact structure, convenient operation and repair, widely used in industrial and mining enterprises, residents' lives, restaurants and hotels, food processing, pharmaceutical industry, and high-purity water preparation. In order to let customers understand the ultraviolet sterilizer, let's introduce it today microwave Electrodeless ultraviolet sterilization equipment Select and use relevant common sense!

Microwave electrodeless Ultraviolet sterilization equipment The following elements should be considered in the selection of

1. Selection of ultraviolet sterilizer: even if the total useful output power is appropriate, the difference in lamp type and quantity will have an important impact on sterilization;

2. Treatment water volume: including the planned water volume, the uniform flow and flow change coefficient have an important impact on the treatment effect;

3. Water quality objectives: the primary objectives include the concentration of suspended solids in raw water, particle size of suspended solids, turbidity, UVC transmittance, bacterial content, etc;

4. Other elements: including environmental elements of equipment application (such as temperature and humidity), and other special requirements of users (such as system device methods).

Microwave electrodeless ultraviolet Sterilization equipment Precautions for application:

1. Ultraviolet rays cannot directly shine on human skin;

2. Ultraviolet rays have certain requirements for the temperature and humidity of the working environment: above 20 ℃, the illumination intensity is relatively stable; In the range of 5~20 ℃, the illumination intensity is added with the increase of temperature. When the relative humidity is below 60%, the sterilization ability is strong. When the humidity is increased to 70%, the sensitivity of microorganisms to ultraviolet light is reduced. When the humidity is increased to 90%, the sterilization ability is weakened by 30%~40%.

3. When there is dust and oil stain on the surface of the ultraviolet lamp tube and sleeve, it will prevent the ultraviolet ray from passing through, so it should be often scrubbed with alcohol, acetone and ammonia.

4. When disinfecting the water, the thickness of the water layer should be less than 2cm, and the water flow should bear 90000UW The illuminating dose above S/cm2 can make the water reach useful disinfection.

5. When the lamp is started, it takes several minutes to warm it to a stable state, and the terminal voltage is high. If it is reopened immediately after sealing, it is often difficult to start, and it is easy to damage the lamp tube and reduce the service life of the lamp tube, so it is generally not suitable to start frequently.