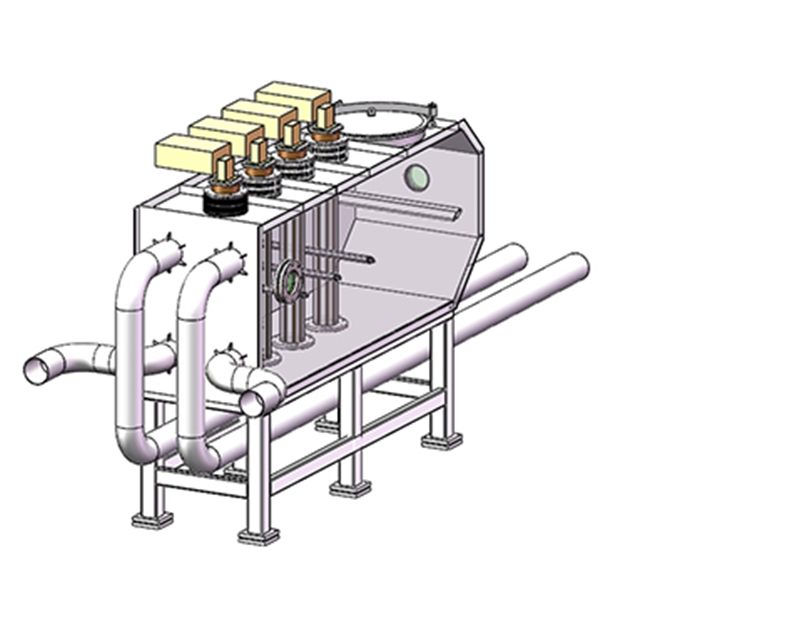

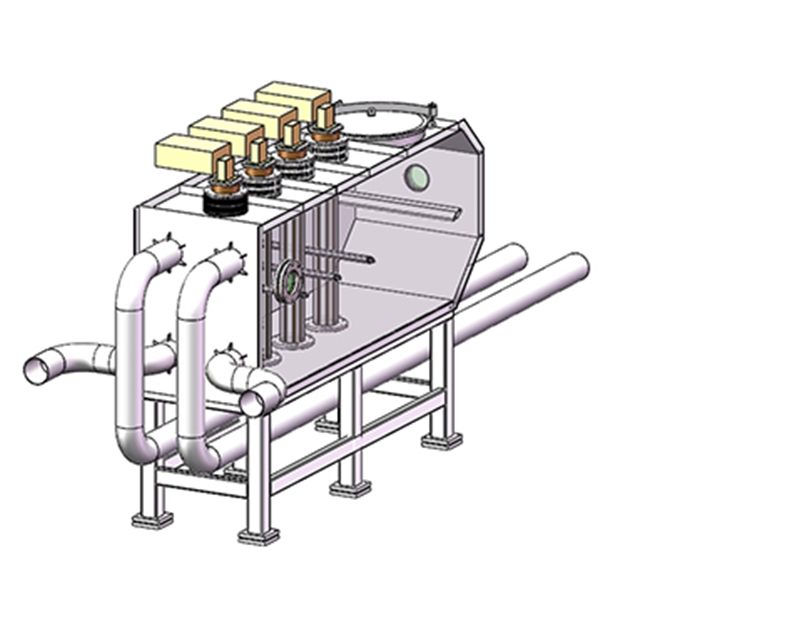

Ultraviolet sterilization equipment for food There are also certain requirements for the appearance of equipment in use, and the requirements are as follows:

1. The welding of equipment shell and framework shall be firm without obvious deformation or burn through defects.

2. The equipment surface shall be evenly sprayed with the same color, and the surface shall be free of flow marks, bubbles, paint leakage and peeling.

3. The appearance of the equipment shall be neat and beautiful without obvious hammer marks and unevenness. The panel instruments, switches, indicator lights and labels shall be installed firmly and correctly.

In order to ensure the stability of the equipment, we need to replace the light tube regularly. The imported light tube has been used for 9000 consecutive hours, or after one year, the ultraviolet light tube should be replaced to ensure a high disinfection rate. When replacing the lamp tube, first pull out the power socket of the lamp tube, pull out the lamp tube, then carefully insert the cleaned new lamp tube into the sterilizer, install the gasket, check for water leakage, and then plug in the power supply. Be careful not to touch the quartz glass of the new lamp tube with your fingers, otherwise the disinfection effect will be affected due to stains.