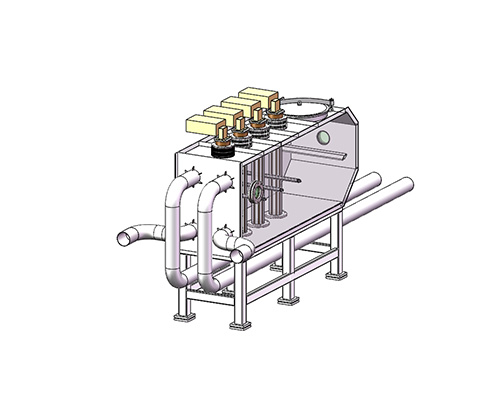

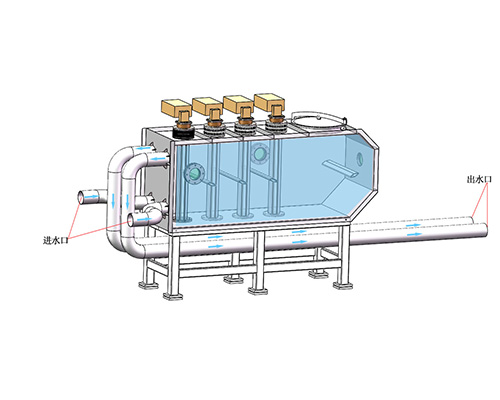

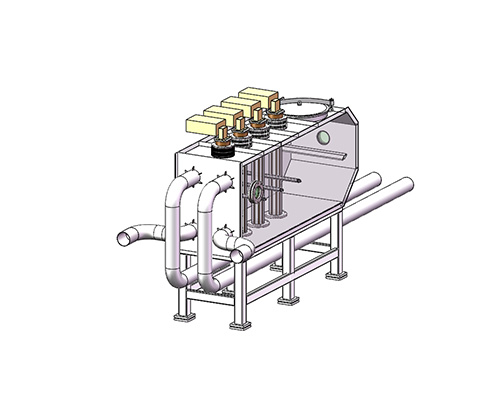

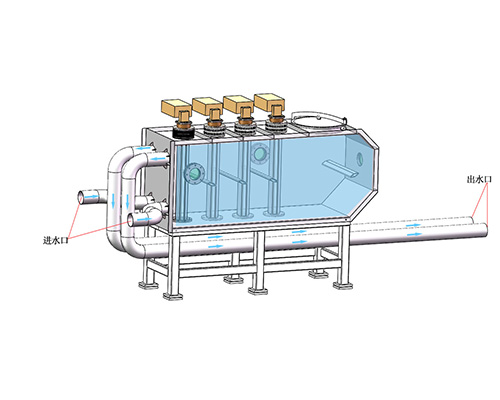

1. Shell material: stainless steel reaction chamber is made of imported 304 stainless steel with thickened wall, and the material is guaranteed.

2. Processing technology: it is welded, and all the passes are welded smoothly without dead corners after punching and drawing. Polishing the high brightness cavity will enhance the ultraviolet radiation intensity and enhance the sterilization effect. The thickened chamber is designed to bear pressure up to 0.6Mpa, and the strict pneumatic and hydraulic test before delivery completely eliminates water leakage.

3. The independently developed sanitary spiral cleaning ring tightly wraps the casing, which is thoroughly cleaned, pollution-free, and suitable for the requirements of clean water quality.

4. The UV lamp is installed in the quartz sleeve in the reactor with high-quality low-voltage and high-strength UV lamp, which is parallel to the water flow direction. The effective working life of the lamp is 10000 hours, resulting in 254nm UV output. The supporting high-efficiency electronic ballast further enhances the life and effect of the whole set of sterilizer, and the sterilization rate of the whole set is up to 99.99%.

5. Quartz casing: the sterilizer adopts quartz casing with high light transmittance (UVT), and the light transmittance of quartz tube is more than 90%, which can be divided into two types: single end opening and double end opening. The excellent ultraviolet penetration rate ensures high intensity ultraviolet output.

6. Electronic ballast: ballast is the core component of the whole system. The company adopts electronic preheating start type and instantaneous high-voltage start type ballasts. Its outstanding advantage is the high stability and reliability of the ballast.

7. Sealing ring: It is made of food grade transparent silica gel and trapezoidal structure made of special mold, so as to avoid water leakage caused by improper installation.

8. UV irradiation intensity sensor/UV irradiation intensity monitor: The UV irradiation intensity sensor can monitor the output intensity of the UV disinfection system in real time online, and output mixed signals of 0-5V or 4-20mA for use by the monitor. The ultraviolet radiation intensity monitor receives the signal provided by the sensor, and can set the radiation intensity alarm value and lamp life according to the requirements. Monitor the system in real time to ensure the normal operation of the equipment.

9. Casing cleaning system: manual or automatic cleaning system. Fully automatic cleaning can be performed online without shutdown. Quartz casing will scale after long-term contact with water, so it must be effectively cleaned. The cleaning ring of this product has a simple structure and is not easy to be aged. The flexible cleaning parts of the cleaning ring can actively adapt to the quartz sleeve. Even if there is a deviation in the installation of the sleeve, the cleaning effect can be guaranteed and the quartz sleeve will not be worn.