Microwave sterilization equipment The microwave processing technology has been widely used in our production and life, and more and more attention has been paid to it. In the process of microwave development in the future, we need to constantly optimize the microwave generator and the processing process in different fields.

1. Sterilization application.

Compared with the traditional high temperature, high pressure sterilization, pasteurization, etc., under the condition of paying small costs, the temperature rises rapidly in a short time to achieve sterilization. It has the advantages of uniform sterilization, no damage to the internal results and material characteristics of objects. In addition, it will not leave other ancillary substances.

2. Dry application.

Microwave technology is mainly used for drying technology. The microwave action is applied to raw materials, semi-finished products or finished products to remove the moisture inside the object. The object can not only meet the dryness, but also ensure the freshness of the object, and will not become moldy due to excessive moisture. After microwave drying, not only the moisture content is reduced, but also the distribution is uniform, which greatly meets the industrial demand.

3. Extract the application.

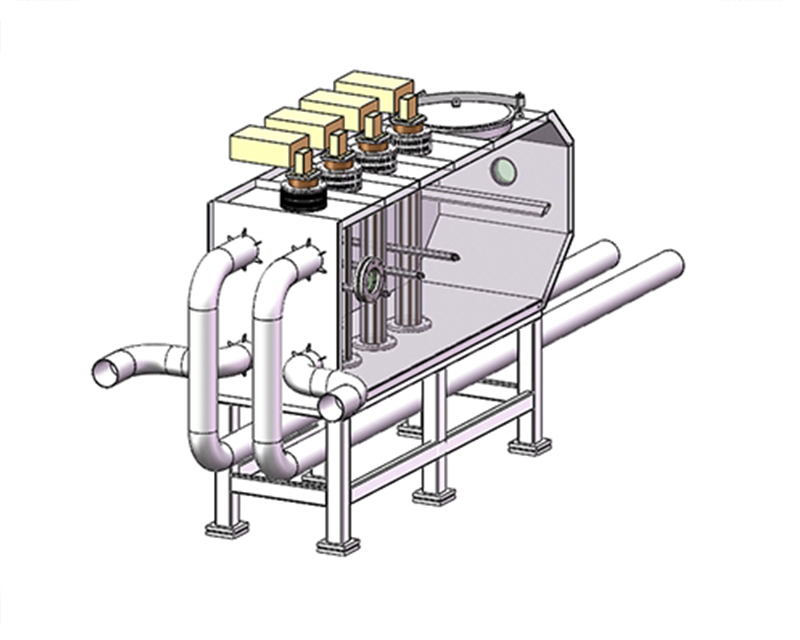

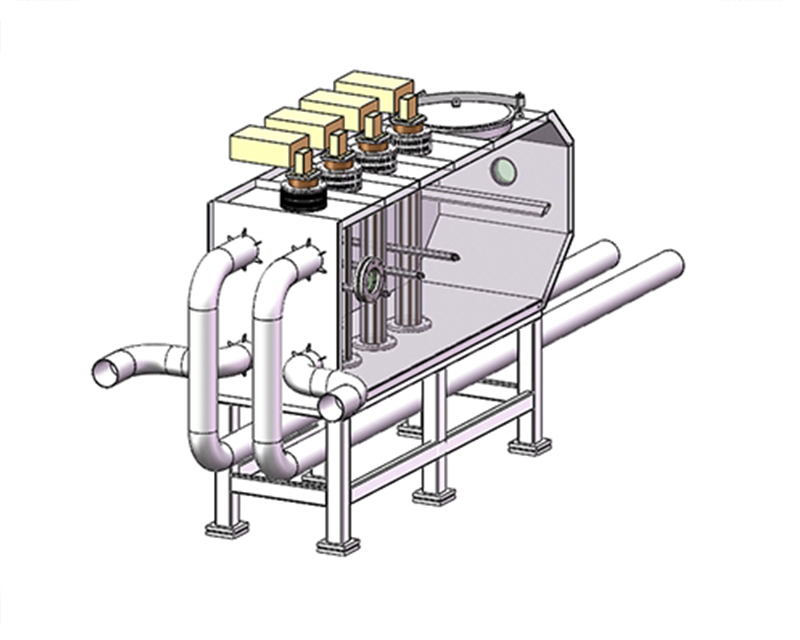

Microwave electrodeless ultraviolet sterilization equipment The specific mechanism is to infiltrate the materials to be extracted through the high-frequency traditional ability of microwave radiation, so that the vascular bundle and glandular cell system in the target can absorb a certain amount of microwave energy, the internal temperature rises, the internal stress increases, and the cells break. The micro blog is used for processing to improve production efficiency. At the same time, the purity of extracted substances is high, and the environmental pollution is less than that of traditional extraction methods, so the application prospect is broad.